目錄大綱 [hide]

- 1 Laser Cutting::

- 2 Laser Engraving:

- 3 Characteristics of Laser Cutting

- 4 III. Characteristics of Laser Engraving

- 5 Ability to Create Complex Patterns and Text

- 6 Delicate and Fine Engraving

- 7 Applicable to Various Materials

- 8 Durable and Long-Lasting Effects

- 9 Applications of Laser Cutting and Laser Engraving

- 10 Personal Applications: Gift Making, Painting and Sculpting Enthusiasts, etc.

- 11 Key Considerations for Choosing Laser Cutting and Laser Engraving Services

- 12 Conclusion

Laser cutting and laser engraving are indispensable processing technologies in modern manufacturing, widely applied in various fields such as electronics, automotive, aerospace, and more. The development of these technologies has brought higher efficiency and quality to the manufacturing industry. Laser cutting and laser engraving are advanced manufacturing techniques that use laser beams for precise cutting and engraving processes. Below are the definitions and principles of laser cutting and laser engraving:

Laser Cutting::

Laser Engraving:

Definition: Laser engraving is a manufacturing technology that uses laser beams to precisely engrave and mark the surface of materials.

Principle: The laser beam is focused on the material’s surface, and by applying high energy to the material, it causes chemical or physical changes in the targeted area, forming the desired patterns, text, or images. The intensity and position of the laser beam can be controlled to achieve high-precision engraving results.

These definitions and principles make laser cutting and laser engraving essential tools in modern manufacturing. Their high precision and flexibility have made them widely used in various industries, including metalworking, electronics manufacturing, advertising production, and artistic creation.

Laser cutting and laser engraving are commonly used processing technologies in modern manufacturing, utilizing laser beams for precise cutting and engraving. Below, the definitions and principles of laser cutting and laser engraving are introduced.

Characteristics of Laser Cutting

Laser cutting is an advanced processing technology with the following features:

- High Precision and Accuracy Laser cutting uses high-energy laser beams to cut materials, enabling highly precise cutting details. This high-precision cutting technology can complete intricate cuts in a very short time while ensuring smooth and consistent cutting edges.

- Applicable to Various Materials Laser cutting technology can be applied to various materials, including metals, plastics, wood, textiles, and more. Cutting of different materials is controlled by different laser settings and parameters, making laser cutting a very flexible and versatile manufacturing method.

- Non-Contact Process Laser cutting is a non-contact processing technology, meaning there is no physical contact with the material during the cutting process. This is crucial as it reduces material damage and contamination, while also minimizing wear and maintenance of cutting tools.

- Speed and Efficiency Laser cutting operations are extremely fast and efficient. The laser beam can complete cuts in a very short amount of time, enhancing production efficiency. Furthermore, laser cutting can be automated, reducing human intervention, further improving production efficiency and saving costs.

The characteristics of laser cutting make it widely applicable in various fields, including industrial manufacturing, crafts, architecture, and home decoration. It provides manufacturers and designers with an efficient, accurate, and reliable cutting solution.

III. Characteristics of Laser Engraving

Laser engraving is a precise and versatile processing technology with the following features:

Ability to Create Complex Patterns and Text

Laser engraving can create intricate patterns and text. Since the laser beam can be precisely controlled, it can achieve very delicate and complex engravings. This makes laser engraving an ideal technology for creating artwork, signage, and decorative items.

Delicate and Fine Engraving

Laser engraving can achieve very delicate and fine engraving results. It uses high-energy laser beams to directly engrave the surface of an object, allowing for extremely high engraving precision and detail. This makes laser engraving suitable for applications requiring highly accurate patterns and text engravings, such as jewelry, crafts, and business cards.

Applicable to Various Materials

Laser engraving can be applied to various materials, including wood, metal, plastic, leather, and stone. Different materials respond differently to laser, so the best engraving effects can be achieved by adjusting parameters such as laser power and speed. This makes laser engraving a versatile processing technology that can be used for different materials.

Durable and Long-Lasting Effects

Since laser engraving directly marks the surface of an object, the engraving effect is highly durable and long-lasting. Compared to other traditional marking technologies, laser engraving provides a more robust engraving that does not fade or wear down over time or due to environmental changes. This makes laser engraving ideal for products and materials that require long-term use and display.

The features of laser engraving make it a widely used processing technology in multiple fields and industries. Whether in manufacturing or art creation, laser engraving offers precise, durable, and diverse engraving effects.

Applications of Laser Cutting and Laser Engraving

Laser cutting and laser engraving are applications of modern technology, widely used across various industries. Below are their industrial and personal applications:

- Industrial Applications: Manufacturing, Media, Art, and Design Laser cutting and laser engraving are widely applied in various industries, including manufacturing, media, and art/design. Here are some common industrial applications:

- Manufacturing: Laser cutting and engraving technologies are used to create parts and products made of metal and non-metal materials. They enable high precision and high-efficiency cutting and engraving.

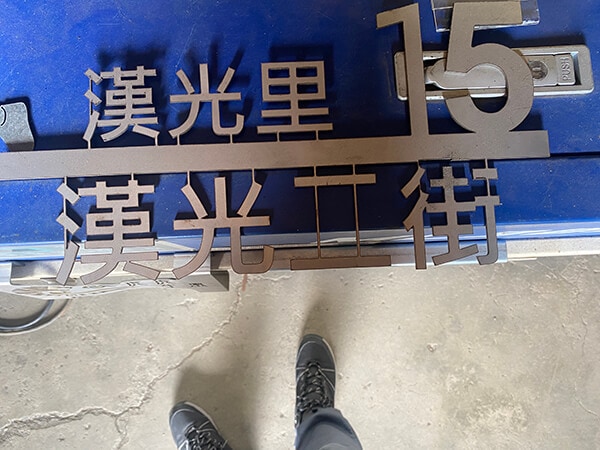

- Media Industry: Laser cutting and engraving technologies can be used to create and produce various flat and three-dimensional media works, such as logos, labels, and signs.

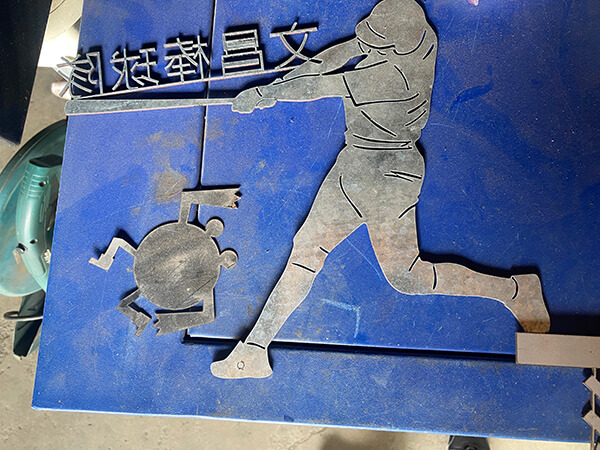

- Art and Design: Laser cutting and engraving technologies offer endless creative possibilities for artists and designers. They can be used to create artwork, sculptures, paintings, jewelry, and more.

Personal Applications: Gift Making, Painting and Sculpting Enthusiasts, etc.

Laser cutting and laser engraving technologies are not only suitable for businesses and industries but are also widely used for personal purposes. Here are some common personal applications:

- Gift Making: Laser cutting and engraving technologies can transform personal designs and messages into unique and meaningful gifts through cutting and engraving, such as personalized nameplates, mascots, and more.

- Painting and Sculpting Enthusiasts: Laser cutting and engraving technologies can help painting and sculpting enthusiasts create more precise and intricate works. For example, they can use a laser cutter to cut complex templates or use a laser engraving machine to create delicate engravings on different materials.

In summary, laser cutting and laser engraving technologies play important roles in various industries and personal applications, offering more possibilities for manufacturing, creation, and decoration. Whether in manufacturing or the art world, laser cutting and engraving are powerful tools and technologies worth exploring.

Key Considerations for Choosing Laser Cutting and Laser Engraving Services

Laser cutting and laser engraving are commonly used manufacturing methods in modern industries, capable of meeting high-precision and high-efficiency production needs. When selecting laser cutting and engraving services, here are the key factors to consider:

- Advancement of Machines and Technology Ensure that the service provider has the latest laser cutting and engraving machines, as well as advanced processing technologies. This will help ensure that your products meet high precision and quality standards.

- Material Selection and Processing Capabilities Ensure that the service provider has the capability to handle various common materials (such as metal, plastic, wood, etc.). This will ensure that your processing needs for different materials can be met.

- Pricing and Delivery Time Compare the pricing and delivery times of different service providers to ensure that you get a reasonable price and receive your products on time.

These are essential factors to consider when choosing laser cutting and laser engraving services. By ensuring that the service provider has advanced machinery and technology, the ability to process multiple materials, and offers reasonable pricing and delivery time, you can ensure that your products are produced on time and with precision.

Conclusion

Laser cutting and laser engraving are common processing technologies in modern manufacturing. They have unique features and wide applications. Here are some conclusions and key points to consider:

- Characteristics and Applications of Laser Cutting and Laser Engraving

- Laser cutting is a precise and efficient manufacturing technology that can cut various materials, such as metals, wood, plastics, etc.

- Laser engraving can create intricate patterns and text on the surface of materials, making it suitable for personalized gifts, labels, decorations, etc.

- Both laser cutting and engraving are non-contact processes, reducing the risk of material damage and contamination.

- The results of laser cutting and engraving are precise and consistent, ensuring high-quality finished products.

- Laser cutting and engraving are flexible and can be customized according to customer needs.

- Importance of Choosing the Right Service Provider

- It’s important to choose a reputable and experienced service provider. They should have advanced equipment and professional technicians.

- Ensure that the provider can offer customized solutions to meet your specific needs.

- Understand the supplier’s delivery time and pricing to ensure they align with your budget and timeline.

- Pre-assess the supplier’s customer reviews and case studies to determine their work quality and service level.

When selecting laser cutting and laser engraving service providers, these conclusions and considerations will help you make an informed decision, ensuring that you receive high-quality processing services.