目錄大綱

Precision metal laser cutting isn’t just a service—it’s the game-changer that laser marking factories have been waiting for. When it comes to melding top-tier accuracy with unmatched efficiency, this technology stands leagues above traditional methods. With advanced lasers carving through everything from everyday stainless steel to exotic nitinol, manufacturers unlock new realms of possibility that drive innovation and precision like never before.

Mastering Materials with Laser Cutting

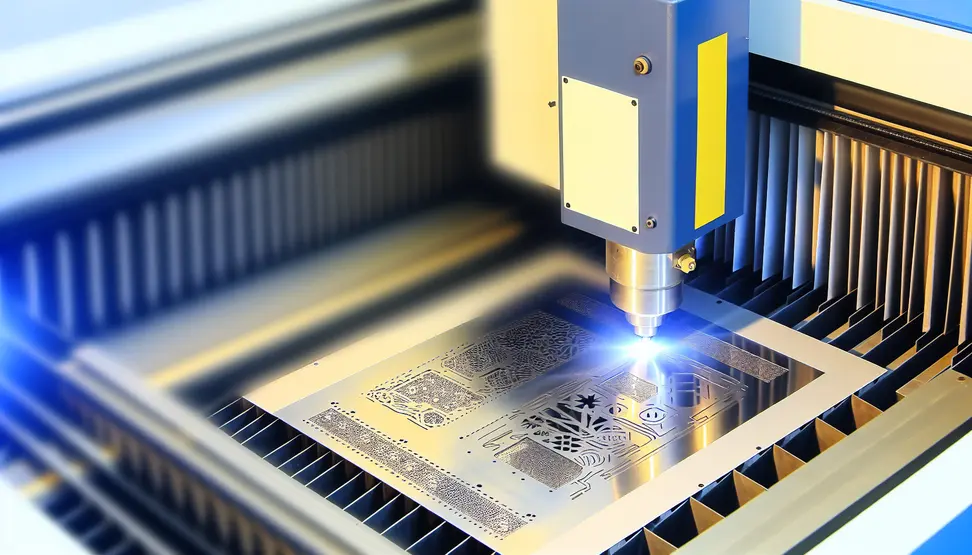

Think laser cutting is just for basic metals? Think again. Precision laser services conquer a stunning variety of materials—robust stainless and mild steels up to 25 mm thick, lightweight aluminum slices reaching 16 mm, and reflective metals like copper and brass that once stumped many cutting technologies. Not to mention specialty alloys like titanium, MP35N, and nitinol that power critical medical and aerospace applications. Thanks to cutting-edge fiber lasers and sophisticated automation, flat sheets, tubes, and even micro-holes with ±0.013 mm tolerances are no sweat. Plus, with value-added services from finishing to welding, laser cutting is an all-in-one powerhouse.

Curious how it stacks up? Dive deeper into the advantages of steel laser cutting.

Next-Level Accuracy: Fiber, CO₂ & Femtosecond Lasers

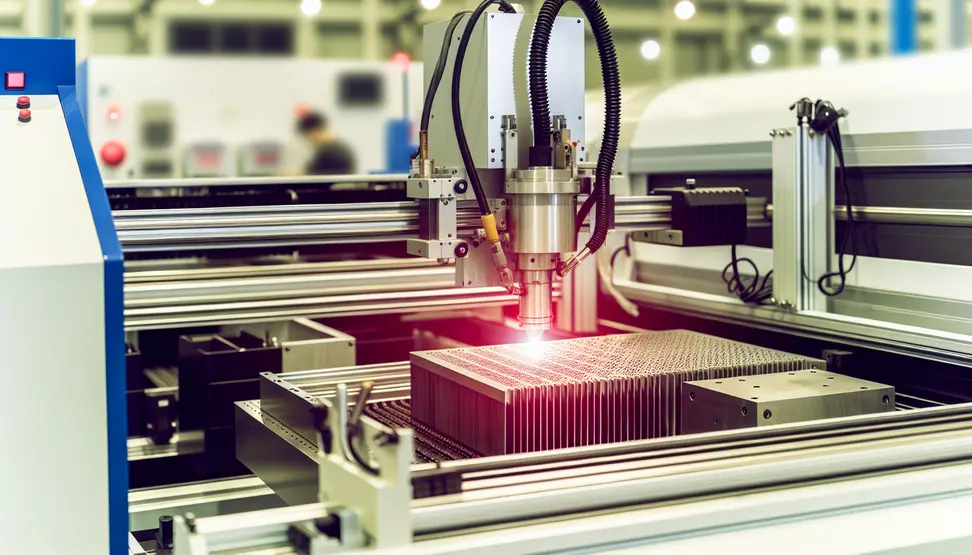

At the heart of precision? Fiber lasers leading the charge with their high efficiency, compact footprint, and lightning-fast, crisp cuts—crucial for reflective metals and tight geometries alike. CO₂ lasers keep their spot for niche materials and thinner sheets, while femtosecond lasers offer near-thermal-free ultrafine processing for ultra-sensitive medical tubes and micro-machining.

Smarter automation means CNC and CAD/CAM integration deliver real-time path tweaks. Autofocus laser heads adjust on-the-fly to material thickness, and high-torque drives nail micrometer positioning. The results? Kerf widths down to 0.10 mm, repeatability within ±0.02 mm, and production running lights-out. For the tech-savvy, check out the full scoop in this laser cutting methods comparison.

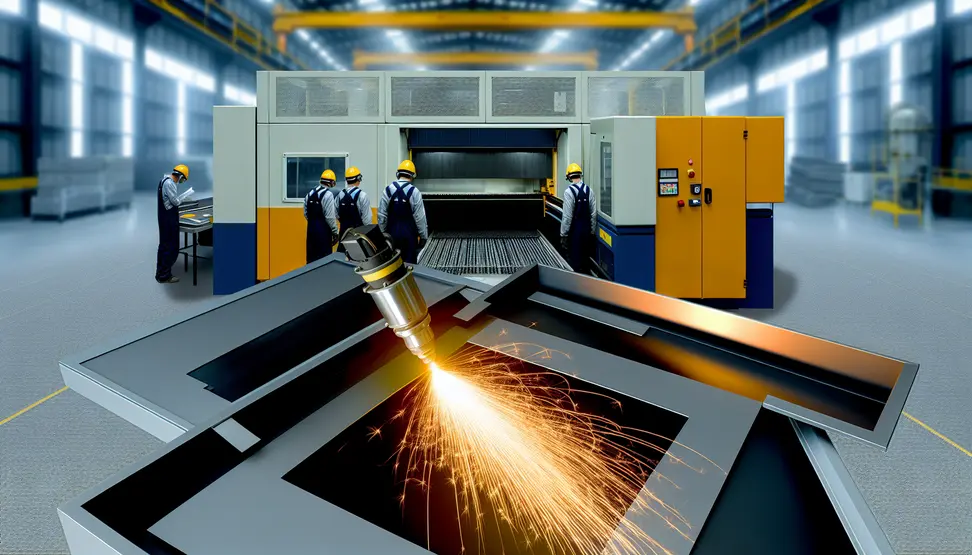

Precision in Action: Metal Laser Cutting’s Impact Across Industries

From high-stakes automotive safety parts to intricately engineered aerospace components, laser cutting is an industry staple. Medical and dental sectors push the limits with surgical tools and stents demanding ±0.013 mm precision—exactness that can save lives. Robotics, industrial machinery, and consumer electronics all reap benefits too, enjoying clean edges, rapid prototyping, and the agility to innovate without compromise.

Minimized waste and superior edge quality aren’t just perks—they’re industry expectations now. More insights? Explore steel laser cutting’s role in modern metalworking.

Finding the perfect laser cutting partner is about more than machines—it’s about the full spectrum of services and expertise they bring to the table. Expect providers to tackle diverse metals including specialty alloys, equipped with cutting-edge fiber and femtosecond lasers, plus engineering guidance that optimizes CAD designs and boosts cost-effectiveness. Integrated services like bending, welding, and finishing streamline your workflow, while fast prototyping, transparent pricing, and tight quality controls keep your projects on track.

Still deciding on the cutting method? This comparison on method selection lays out the nuances that matter.

Empowering Laser Marking Innovation

Precision metal laser cutting services arm laser marking factories with unmatched accuracy, speed, and material flexibility. Whether it’s aerospace-grade titanium or everyday stainless steel, these services elevate production from first prototype to full-scale manufacturing with confidence and efficiency. Backed by expert providers and flexible options, you can streamline operations, cut costs, and push product quality to new heights.

Ready to upgrade your laser marking workshop? Contact us today and discover how advanced laser cutting can be your secret weapon for superior marking and manufacturing:

Learn more: https://en.fiberglass-tubes.com/contact-us/

About Baixiang

Baixiang’s roots run deep in office system furniture, but our eyes are set firmly on the future. With continuous investments in cutting-edge machinery and factory automation, we deliver consistent, high-quality precision laser marking and metal processing solutions. Partner with Baixiang to bring your manufacturing capabilities to the forefront of innovation.